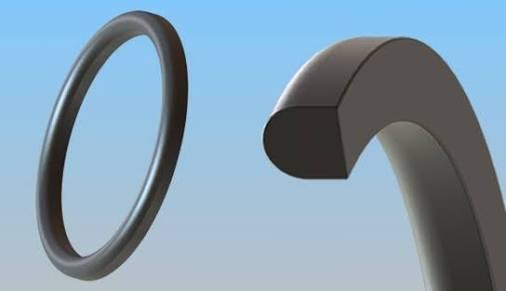

O-RINGS

The O-ring is the most versatile of all seals, with the particular advantage of simplicity and low cost. It is suitable for the both static and dynamic sealing in almost every field of application upto 1500 PSI pressure within the operating limits and material characteristics, provided these seals are technically desig+ned and applied. Selection of an elastomer(Polymers) largely depends on application and physical properties required for an O-ring.

RECTANGULAR RINGS

A basic alternative to O-ring is the square or rectangular ring, moulded in an elastomeric material or sometimes punched from Sheet stock. In most cases however the rectangular ring will offer an advantage over the O-rings

QUAD AND H- RINGS

Q & H Rings, normally achieve their best performance as dynamic seals with medium Pressure and reciprocating actions having a lower frictional resistance then O-ring at pressures upto about 600 PSI

Q & H Rings, normally achieve their best performance as dynamic seals with medium Pressure and reciprocating actions having a lower frictional resistance then O-ring at pressures upto about 600 PSI

D- RINGS SEALS

A further variation on the O- ring theme is D- ring. This provides a greater base contact area than an O- ring at low pressure. It is a type of simple seal which may be advantageous for specific applications when a normal O- ring is not fully satisfactory.

A further variation on the O- ring theme is D- ring. This provides a greater base contact area than an O- ring at low pressure. It is a type of simple seal which may be advantageous for specific applications when a normal O- ring is not fully satisfactory.

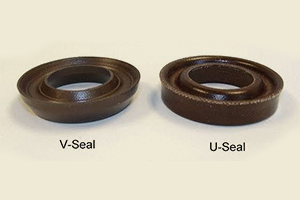

U SEAL

The U- seal is the oldest design of pressure energised hydraulic seal and provides particularly good

sealing at low to moderate pressures. U seals can be used single or in sets.Main variations on the U seal are round base & flat base. Also one leg may be shortened and lip reduced to produce either external or internal seals.

V- RINGS

The V- rings offers the advantage of a smaller cross-section for sealing ability. It is seldom used singly, however, but rather in sets with suitable header when it is capable of providing sealing against extremely high pressure with only a light preload. Performance varies with the angle of 'Vee'

The V- rings offers the advantage of a smaller cross-section for sealing ability. It is seldom used singly, however, but rather in sets with suitable header when it is capable of providing sealing against extremely high pressure with only a light preload. Performance varies with the angle of 'Vee'

CHEVRON TYPE SEALS

Chevron type seals have an extremely wide application for medium to heavy duty hydraulic and similar services. Normally seals are manufactured from canvas impregnated with Nitrile/Viton rubber and is used in the form of set consisting of top and bottom rings. The number of V-rings in a set depends upon the pressure to be sealed. Functions satisfactorily upto 5000 PSI.

Chevron type seals have an extremely wide application for medium to heavy duty hydraulic and similar services. Normally seals are manufactured from canvas impregnated with Nitrile/Viton rubber and is used in the form of set consisting of top and bottom rings. The number of V-rings in a set depends upon the pressure to be sealed. Functions satisfactorily upto 5000 PSI.

CUP FLANGE AND COLLAR SEALS

Basic forms of simple flexible seals includes the cup, flange and the collar. The cup seal has excellent uni-directional sealing properties with low friction but required proper support for proper functioning and stability of the section. It is employed almost exclusively for piston seals. The flange is virtually an internal form of the cup seal and is thus basically a rod seal. It requires proper support. The Collar is simply a variation of the flange, but with the section modified to improve resistance to scuffing and wear. The flange & collar are more used as wiper rings.

WIPERS

Wiper are a special class of seal normally employed for their wiping & scraping action in conjunction with sliding a or reciprocating motions rather than as seals and such, although they may provide and effective sealing action. Their normal application is to remove dust, dirt and similar articles from a surface passing under the wiper and thus provide protection for interior surface of a machine.

TWIN SET PACKING

Combinations of single rings and matching headers are generally known as duplex rings to distinguish them from unit seals (implying integral construction of a combination). The term is applied particularly to combinations of a header with a fork or U- ring section. Other sections allied to separate components(such as O – rings and back – up rings) are more usually referred to as combination seals and dealt with in.

Combinations of single rings and matching headers are generally known as duplex rings to distinguish them from unit seals (implying integral construction of a combination). The term is applied particularly to combinations of a header with a fork or U- ring section. Other sections allied to separate components(such as O – rings and back – up rings) are more usually referred to as combination seals and dealt with in.

OIL SEALS

Oil seals for the shafts are of dynamic type in as much as sealing has to be provided between a rotating shaft and a stationery member. Int he vast majority of cases the internal pressure against which the seal has to work is very low and thus whist a simple lip seal may be adequate its performance depends to a large extent on a suitable unit load being maintained at the seal-shaft interface. The conventional form of Oil seal which is suitable for the majority of applications where the pressure involved is not more than about 5 PSI and the oil (or fluid) to be sealed is clean comprises a moulded elastomeric ring. For the majority of applications where a conventional single lip seal will be suitable, seal selection is based on seven basic points: namely shaft diameter, housing bore diameter and width, shaft speed, working temperature, fluid, pressure differential and service conditions.

Oil seals for the shafts are of dynamic type in as much as sealing has to be provided between a rotating shaft and a stationery member. Int he vast majority of cases the internal pressure against which the seal has to work is very low and thus whist a simple lip seal may be adequate its performance depends to a large extent on a suitable unit load being maintained at the seal-shaft interface. The conventional form of Oil seal which is suitable for the majority of applications where the pressure involved is not more than about 5 PSI and the oil (or fluid) to be sealed is clean comprises a moulded elastomeric ring. For the majority of applications where a conventional single lip seal will be suitable, seal selection is based on seven basic points: namely shaft diameter, housing bore diameter and width, shaft speed, working temperature, fluid, pressure differential and service conditions.